Welcome to our Website

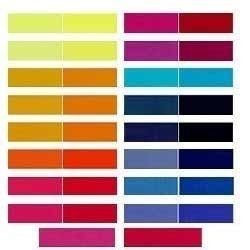

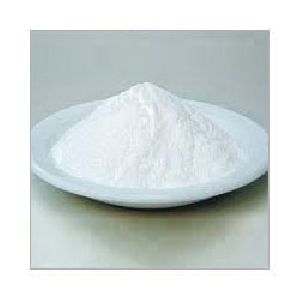

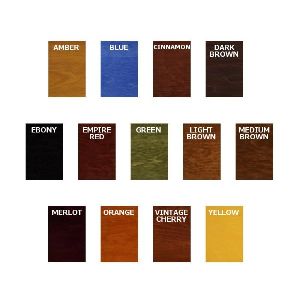

Parshwanath Dyestuff Industries is one of the leading manufacturers, exporters, and suppliers of dyes and colors. We are engaged in offering the Indian and international markets our range of quality based titanium dioxide, food colors, reactive dyes, acid dyes, solvent dyes, non benzidine direct dyes, pigment powder and paste . Ours is an ISO 9001:2000, HACCP and GMP certified company. Our Core purpose is to create value for customer to earn their lifetime loyalty. Making use of the finest quality raw material, we produce and supply a premium range of products. Entire range of products can be made available to the clients in bulk in time-bound manner. Read more...

MANUFACTURER OF PIGMENT POWDER, SOLVENT DYES

Featured Products

Quick Enquiry

Find Us

Mr. Jitendra Patel

I-5617, Phase-II, Vatva, G.I.D.C., Vatva, Ahmedabad, Gujarat - 382445, India

+91-9909903636